The Connolly Expansion Joint is a continuous pour solution for expansion joints in slab on ground applications.

The straight profile guarantees that the load is transferred through the dowels only.

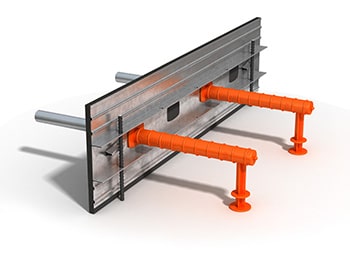

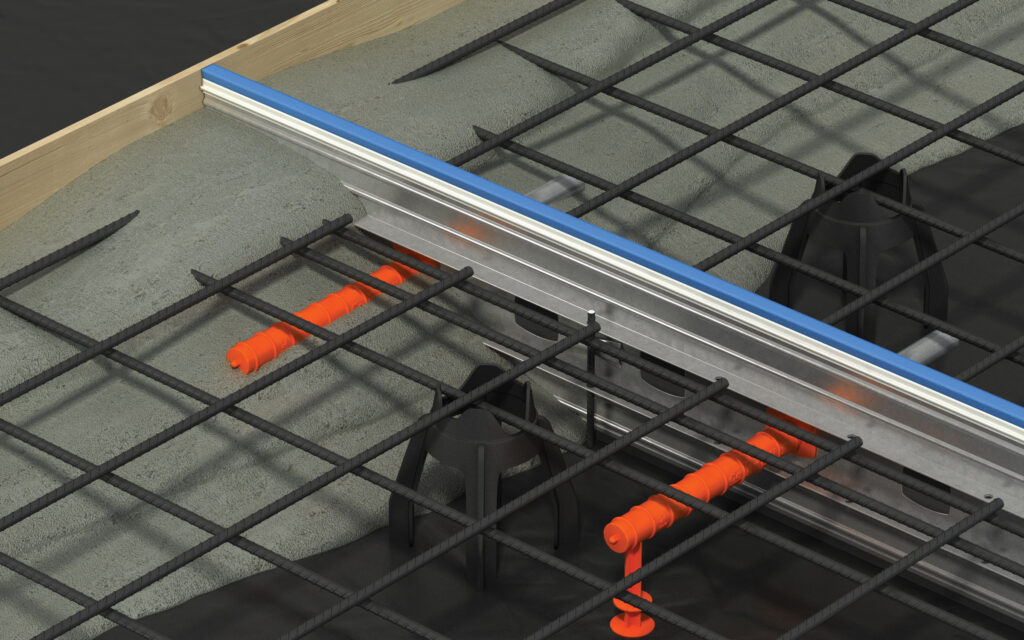

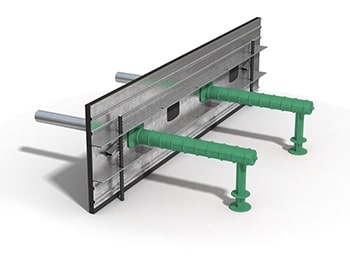

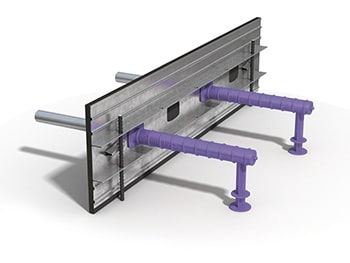

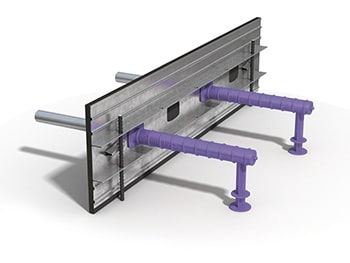

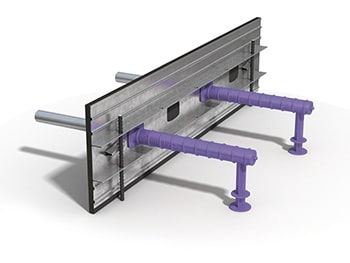

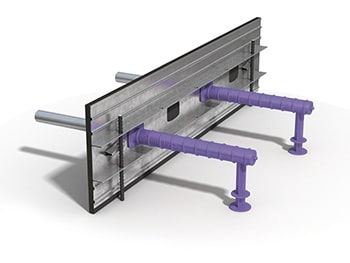

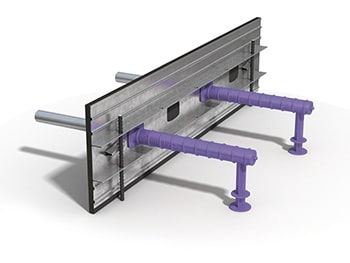

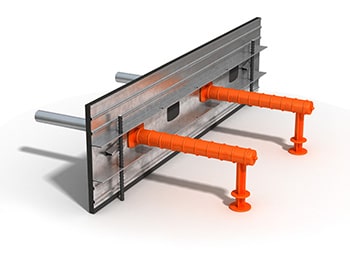

Connolly Expansion Joints are a roll-formed galvanised steel section with 10mm cross-linked foam to provide a leave in place formwork that allows for joint expansion. The profile is fixed in place using the patented peg and wedge system.

Connolly Expansion Joint System (EXJ20030)

The Expansion Joint profile has pre-formed holes which allow it to be used in conjunction with Connolly Universal Dowel Sleeves (UDS). The Universal Dowel Sleeves are installed in the steel section using the patented twist-fix feature. The preformed holes will accommodate round dowels up to 30mm diameter and square dowels up to 24mm.

The Expansion Joint profile is available in 3m lengths for slab thicknesses from 100mm to 200mm. Custom heights, lengths (up to 3m), and dowel configurations are available on request.

A wide range of permanent capping and rebate moulds are available to be used with Connolly Expansion Joints.

Features:

Download the EXJ Installation Guide

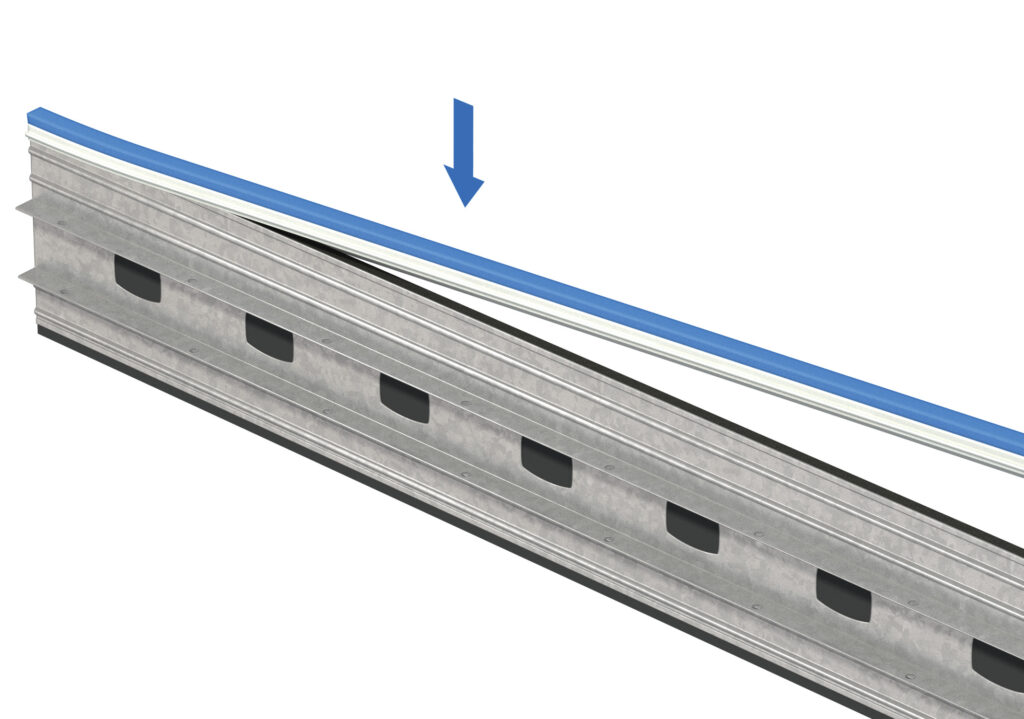

Step 1:

If a cap or rebate mould is specified, install the specified capping on the profile. Press on top until profile clicks in.

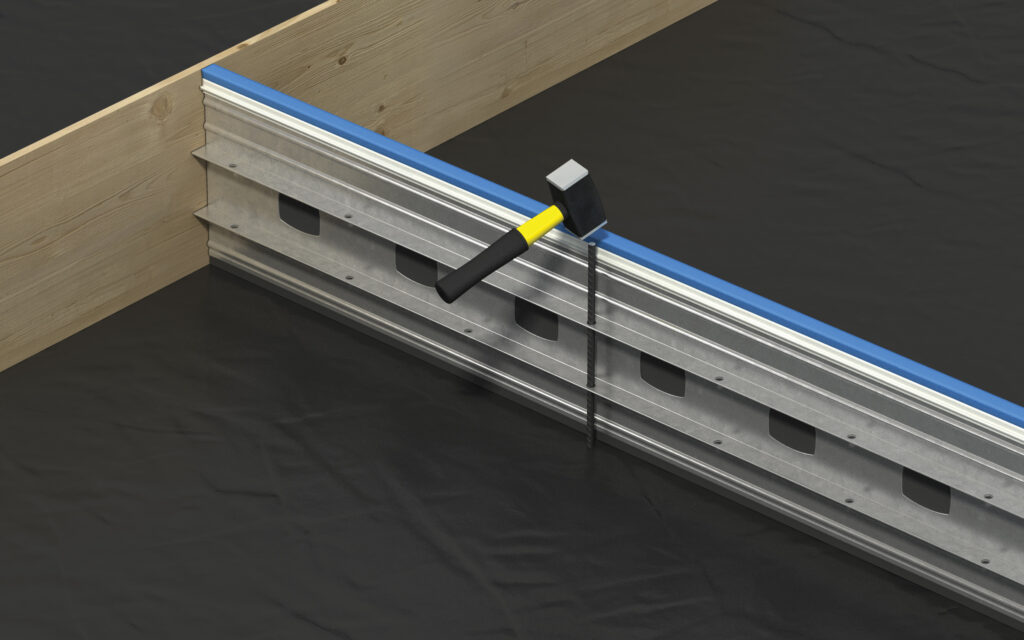

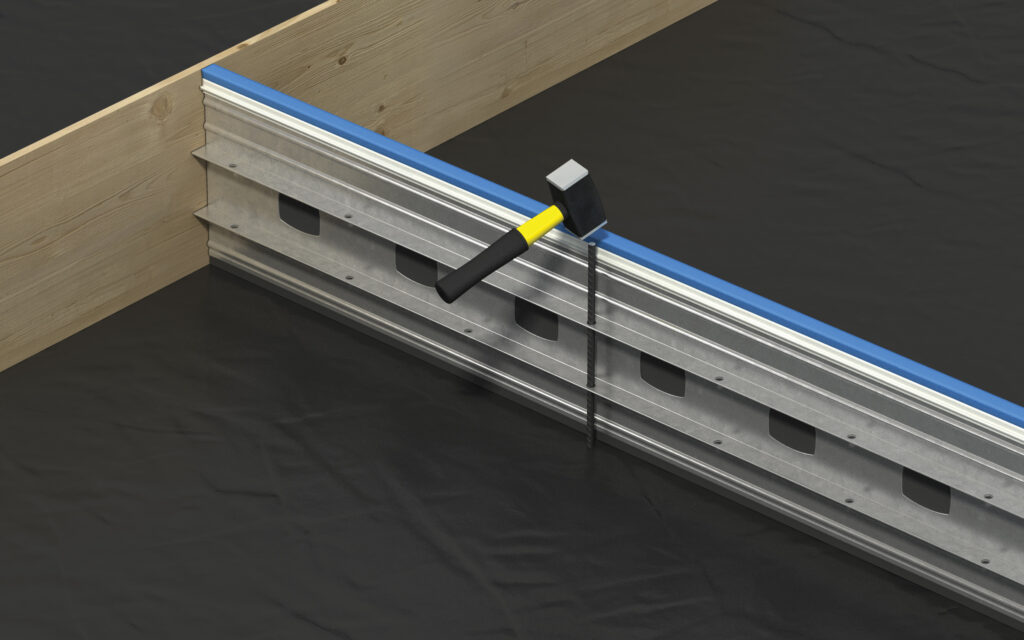

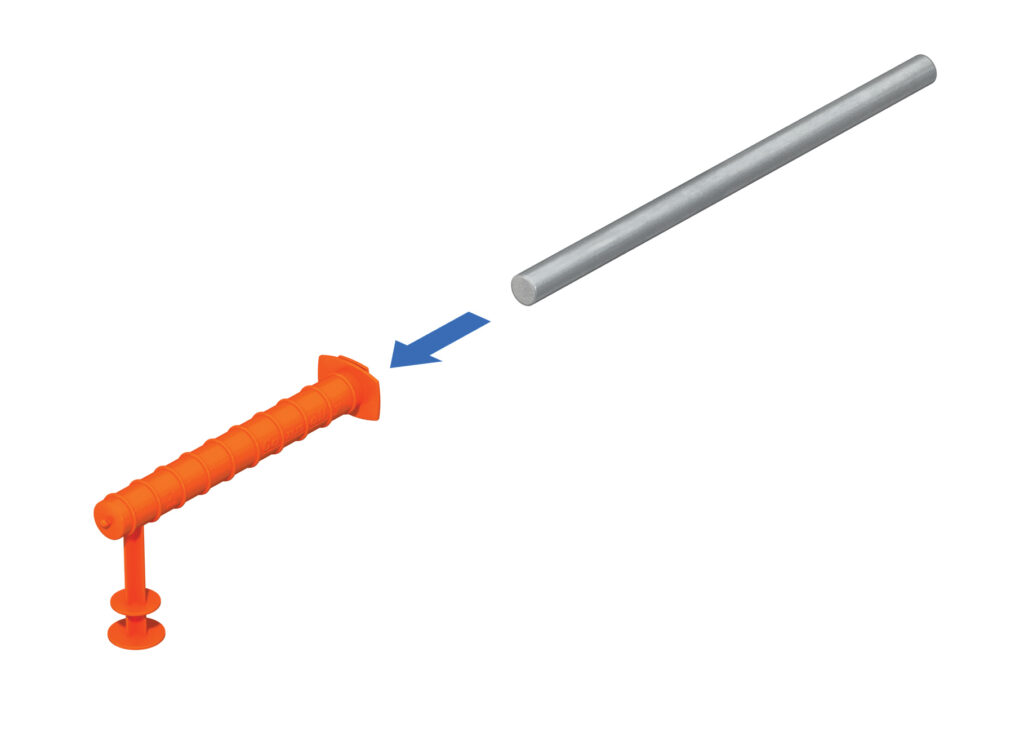

Step 2:

Position Expansion Joint profile in the desired location and drive in the supplied pegs.

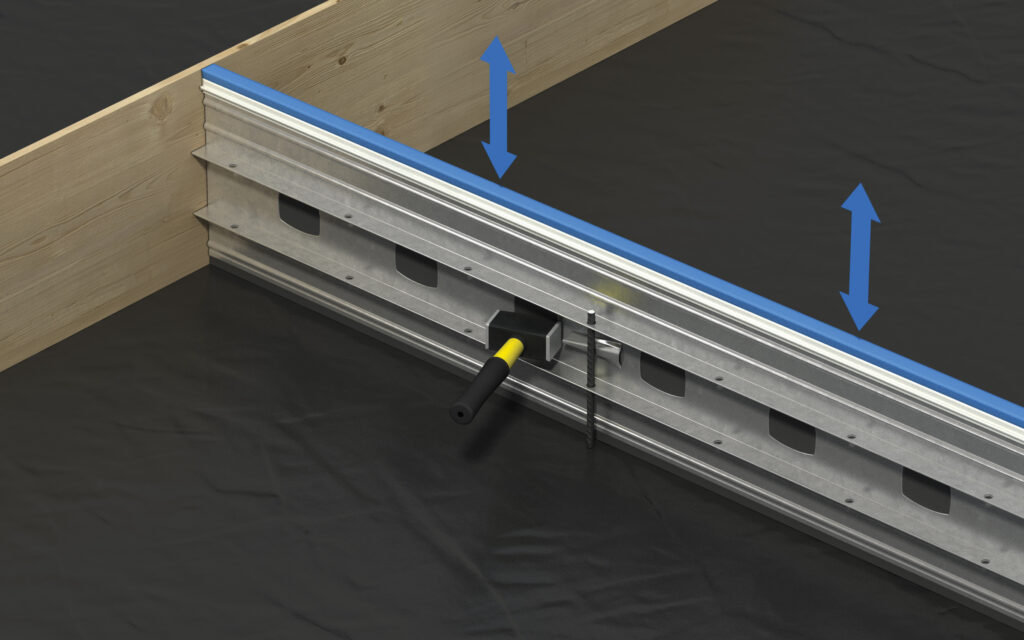

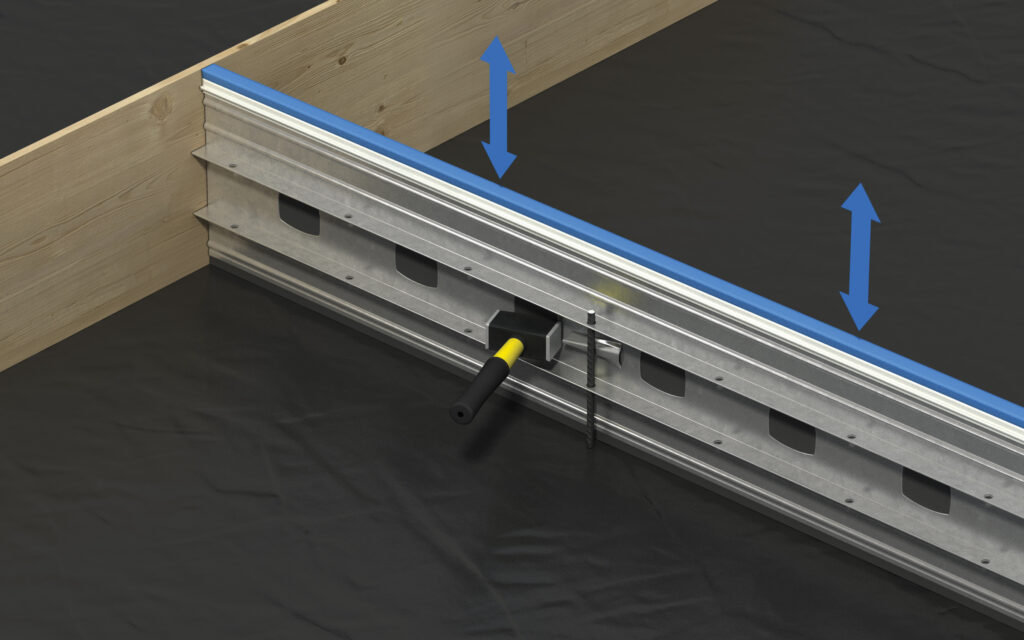

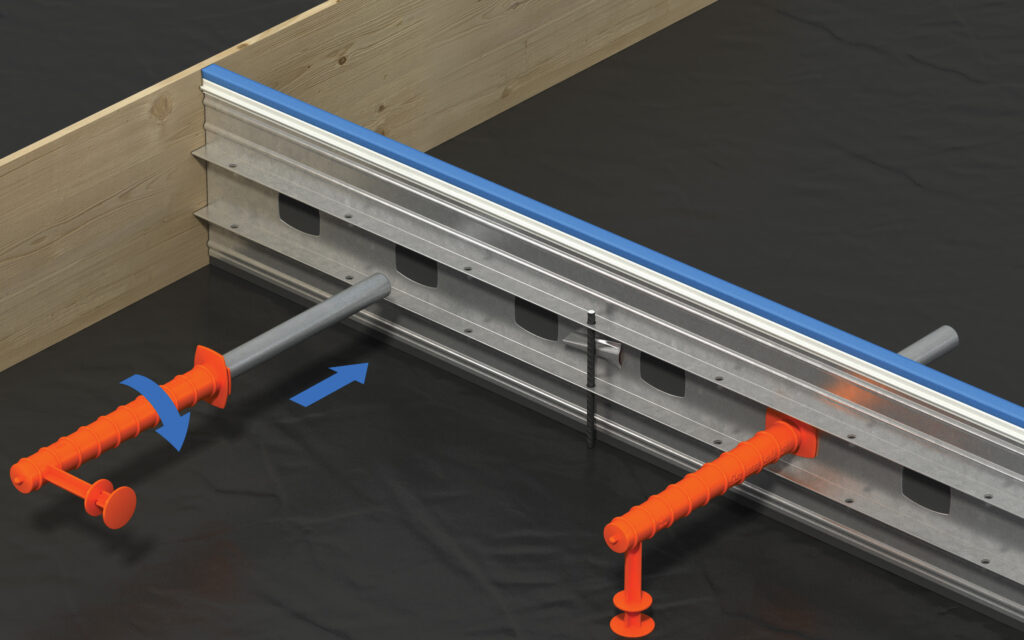

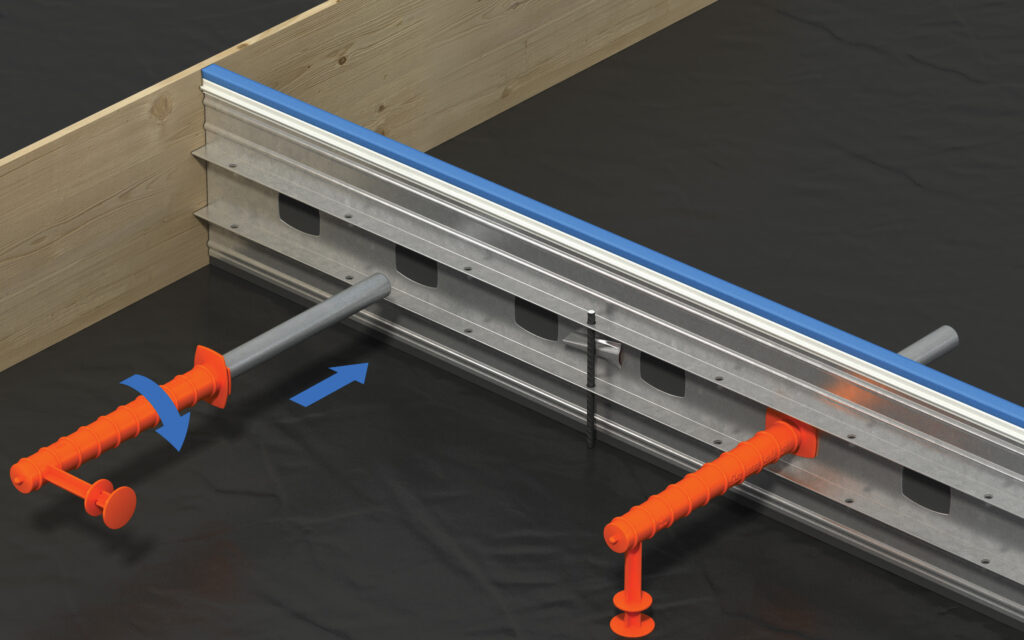

Step 3:

Adjust the Expansion Joint to the correct height and secure by tapping in the supplied wedges.

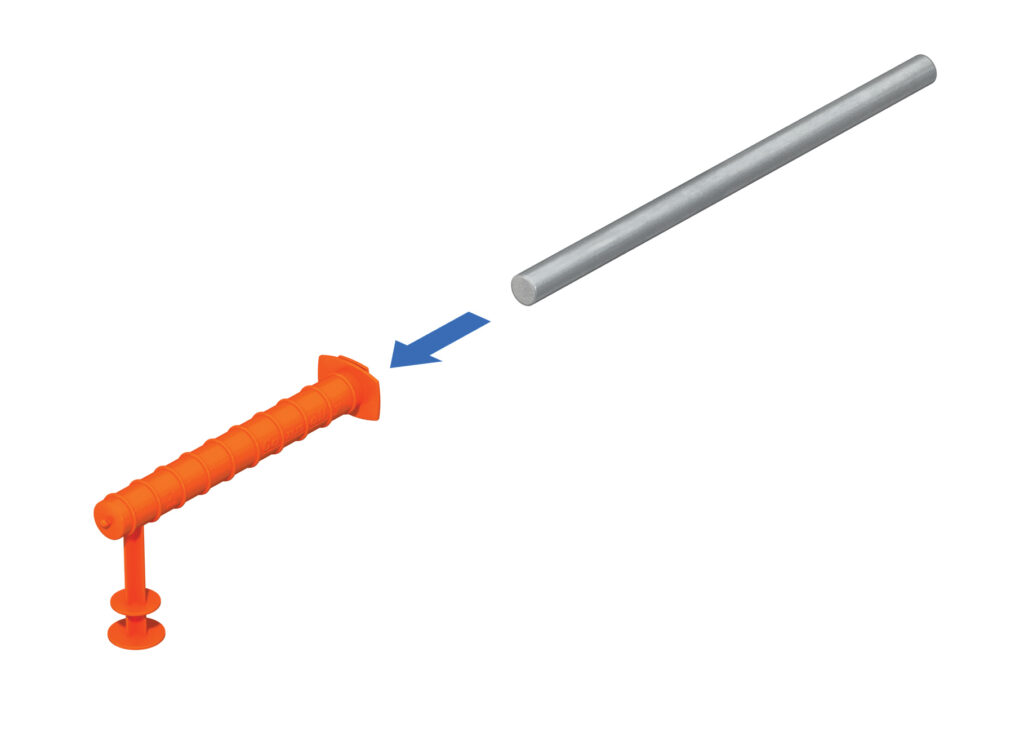

Step 4:

Install dowel in Connolly Universal Dowel Sleeve by pressing all the way to the end of the sleeve.

Step 5:

Install Universal Dowel Sleeve in the Expansion Joint profile by pushing the dowel through the foam at the centre of the pre-punched holes in the metal profile and twist sleeve 90 degrees to fix in place.

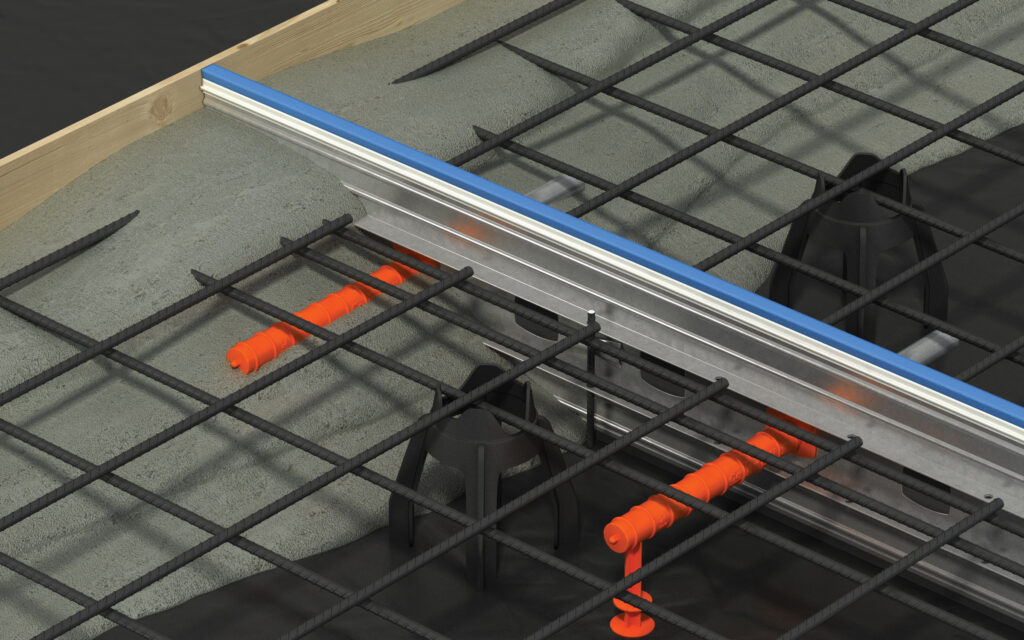

Step 6:

Place reinforcement and pour concrete to both sides of the joint. Finish concrete surface to the top of the expansion joint.

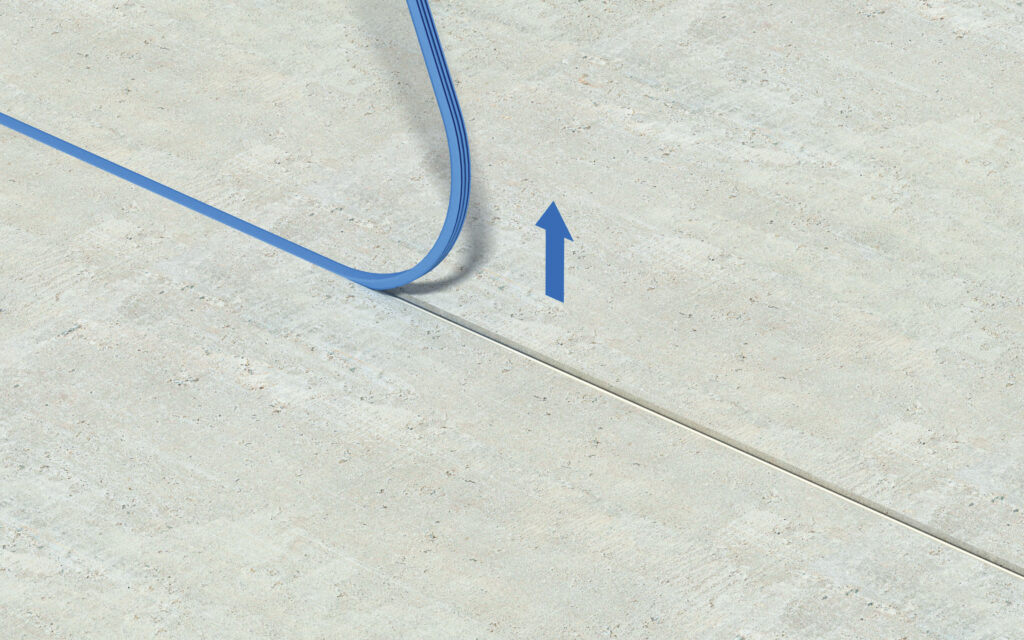

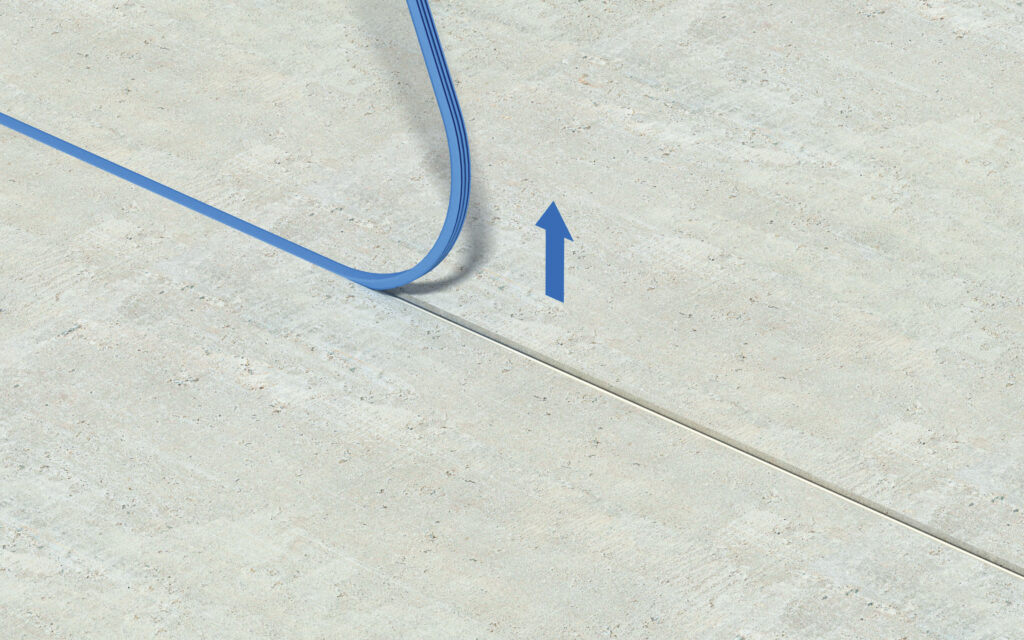

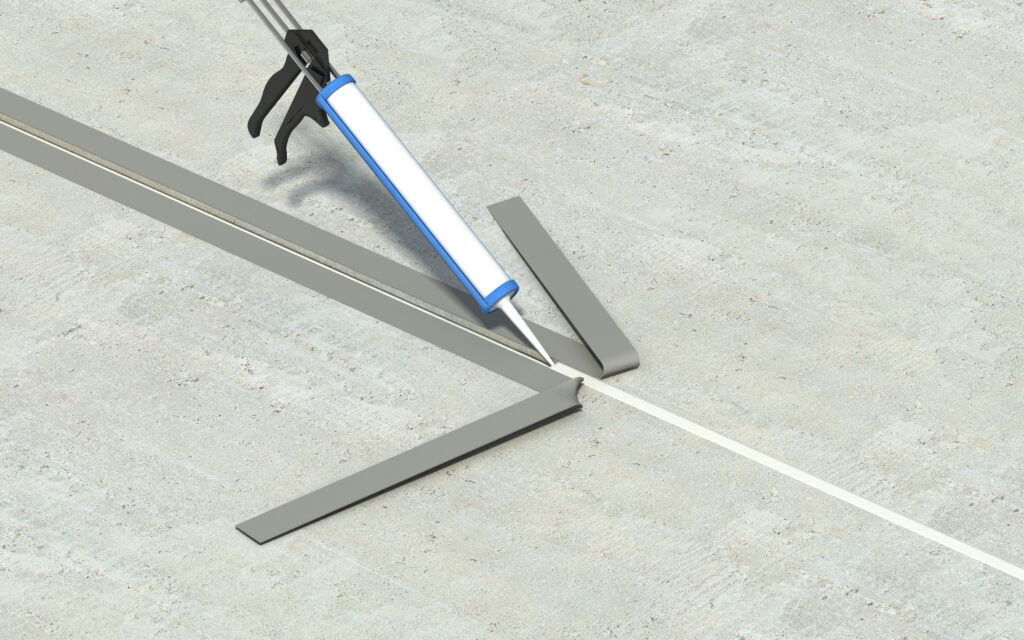

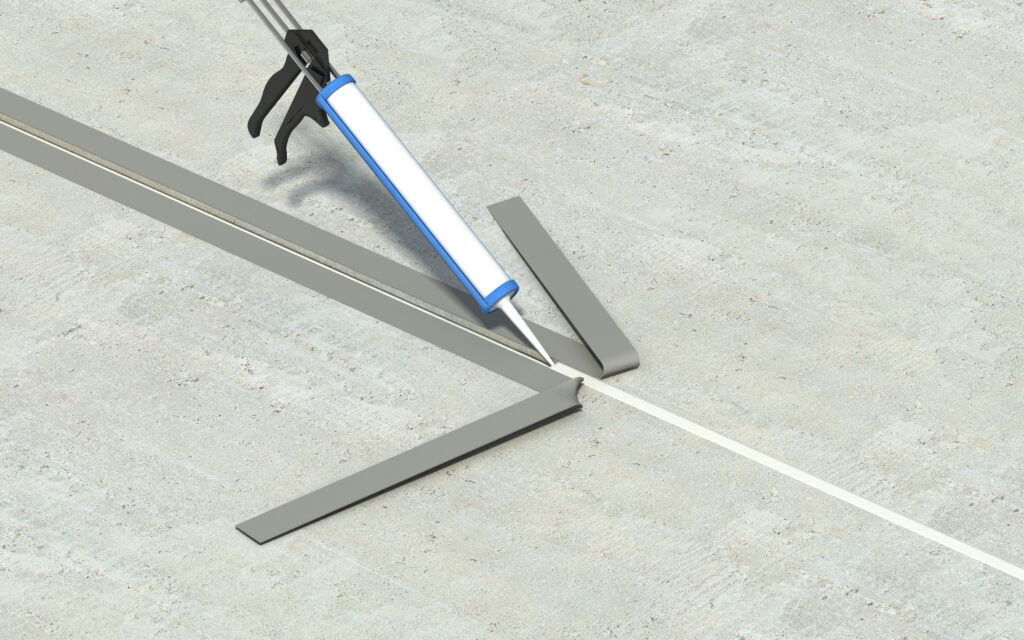

Step 7 (when used with rebate mould only):

Pull out the top profile and apply a sealant to the manufacturer’s specifications.

| Product |   EXJ10030 |    EXJ12530 |    EXJ15030 |   EXJ20030 |

|---|---|---|---|---|

| Properties | ||||

| Description | Expansion Joint System for 100mm slab | Expansion Joint System for 125mm slab | Expansion Joint System for 150mm slab | Expansion Joint System for 200mm slab |

| Slab thickness [mm] | 100 | 125 | 150 | 200 |

| Profile heights [mm] | 87.5 | 123 | 142 | 190 |

| Foam heights [mm] | 100 | 125 | 150 | 200 |

| Length [m] | 3.00 | 3.00 | 3.00 | 3.00 |

| Dowel diameter [mm] | 12 | 16 | 16 | 24 |

| Dowel length [mm] | 300 | 450 | 450 | 450 |

| No of dowels / centres [mm] | 9 / 335 | 7 / 450 | 7 / 450 | 7 / 450 |

Custom lengths (up to 3m), heights and dowel configurations available on request.

For cappings and rebate moulds please visit the Expansion Joint capping page.

Use the form below to send us an email with your enquiry or request for drawings.